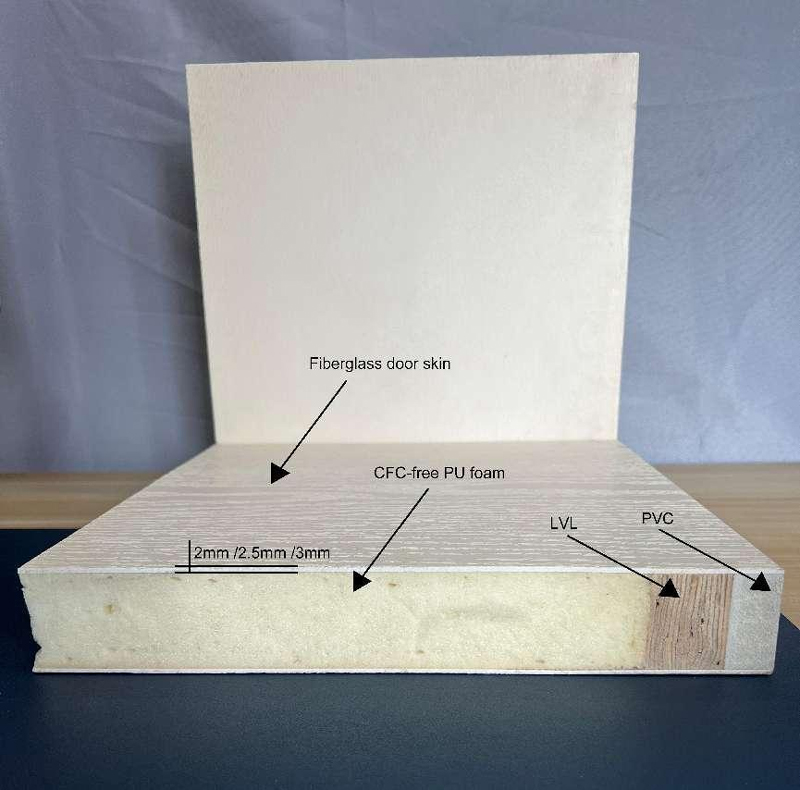

FRP door is made of a sandwich structure, which consists of two layers of high strength molded fiberglass face sheets (Glass Fibre Polymers composites), bonded by liquid adhesive to a high-density heat insulated core Polyurethane Foam, with multilayer board at the side for support and PVC banding. Each component by itself is relatively weak and flexible, however, when combined in a sandwich panel, they produce a stiff, strong yet light-weight structure. Core materials sere to stabilize face sheets against buckling under compression, torsion or bending loads, providing a rigid and highly effective structure. Sandwich concept is one of the most widely accepted forms of composite structures in primary load bearing structures and their construction.

One of the many benefits of FRP fiberglass Doors is the ease of installation. This means they can be fixed in wooden, marble, masonry, ferro cement or FRP Frames, making them the ideal choice for any type of aesthetic looks that need to be achieved.

FRP Frames: We manufacture and supply FRP frames, designed with a cross section of 2.00 mm thick FRP laminates. Core of the frame consists of seasoned hard wood as infill material.

Door Features:

Surface texture: Our superior oak and mahogany textured skin technology with “High Definition Panel Embossments” provides an authentic wood finish look. We provide the real feel and look of a wood textured surface without the disadvantages that natural wood doors come with.

Composite rails on all edges:

Our fiberglass doors have composite (PVC) rails that surround the parameter of the panel making them 100% waterproof. This prevents them from rotting and warping like other fiberglass, steel or wood doors. This is one of the reasons why we offer lifetime warranty.

LVL lumber components:

LVL (Laminated Veneer Lumber)is the strongest man-made wood material. We created the world’s first PVC LVL cap wrap with a tongue-in-groove rail lock system giving our doors a solid frame structure with complete moisture barrier.

Door Core:

Our door core is made of high-density CFC-free polyurethane foam, providing six times the insulation of a traditional wood door. Another advantage of a polyurethane door core is superior sound proofing.

Panel Design:

Both our Executive panel and Recessed panel doors easily meet both the demanding contractor and customer concerns. The elegantly derailed architectural panels feature deep shadow lines that add to any home’s strong curbappeal.

Superiority:

1. Water, Termite and Chemical Resistant

2. Easy to drill, trim, paint, polish and install

3. Light-weight with high strength and stiffness

4. Aesthetically pleasing

5. Cost-effective

6. Maintenance-free

7. Highly modifiable, with many variants and colors

Post time: Sep-27-2022