Pvc profiles

MOONLIT is a distinguished leader in the manufacturing and global export of PVC profiles, setting benchmarks of quality and innovation. Our extensive production capabilities and advanced technology enable us to deliver PVC profiles that cater to diverse requirements across continents. Specializing in a complete range of products, we ensure fast delivery to support the business needs of our valued partners.

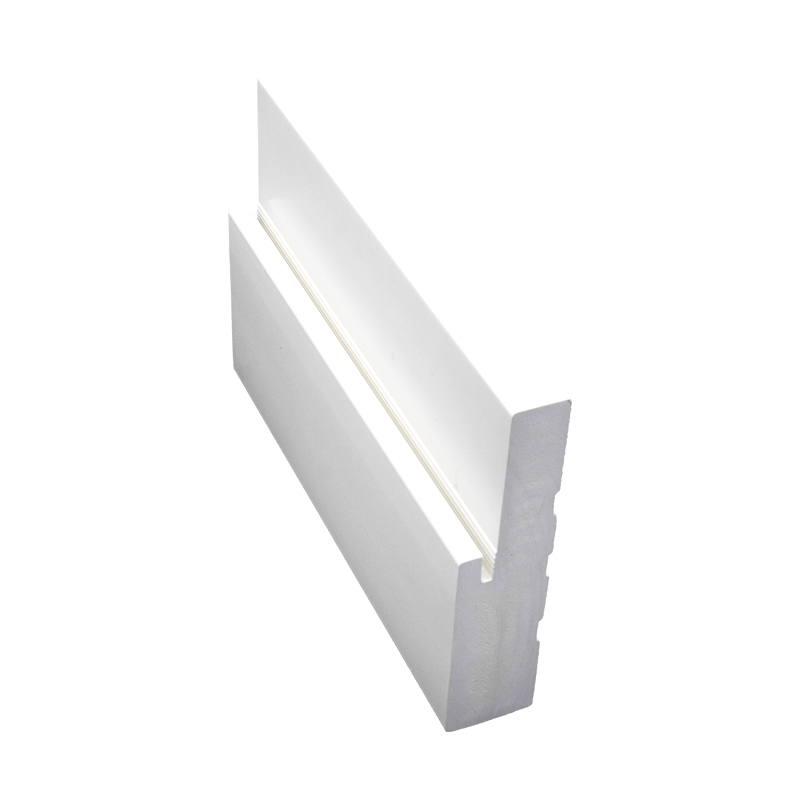

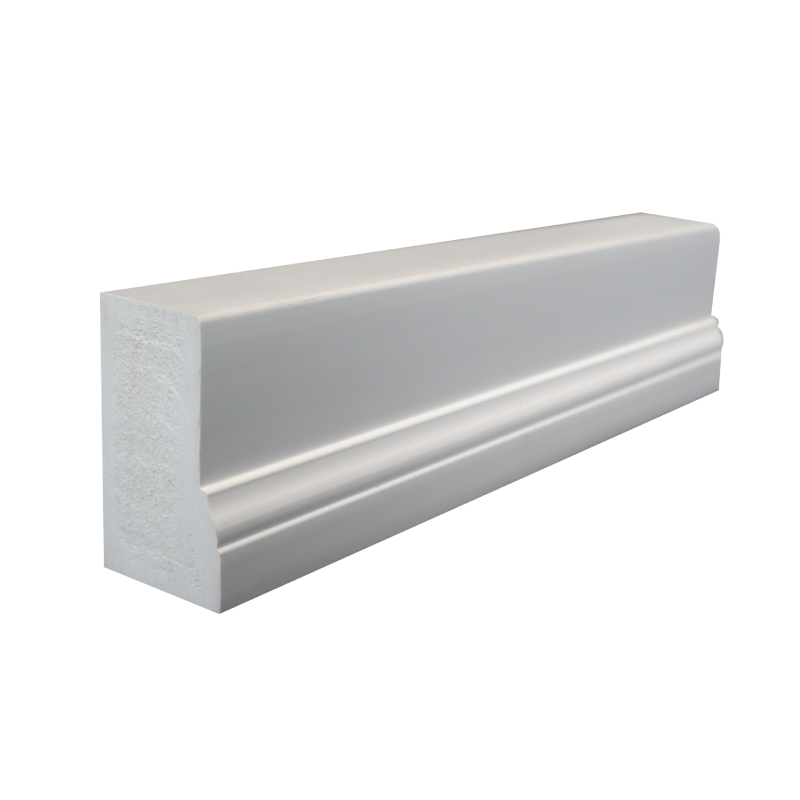

Our PVC profiles, including the robust PVC base board and the elegantly designed PVC door frame, exemplify durability and ease of use. Crafted from premium materials, these profiles offer superior resistance to wear and environmental factors, making them ideal for both residential and commercial installations. The lightweight nature of our products facilitates hassle-free installation, while the variety of designs and finishes allows for a seamless blend with any décor style.

MOONLIT’s commitment to quality and excellence is reflected in our adherence to stringent manufacturing standards, ensuring that every product we deliver meets international benchmarks. We pride ourselves on fostering long-term relationships with our clients, underpinned by sincerity and mutual growth. By choosing MOONLIT, you align with a company that prioritizes innovation and reliability, offering solutions that enhance value and performance in every project.

Our PVC profiles, including the robust PVC base board and the elegantly designed PVC door frame, exemplify durability and ease of use. Crafted from premium materials, these profiles offer superior resistance to wear and environmental factors, making them ideal for both residential and commercial installations. The lightweight nature of our products facilitates hassle-free installation, while the variety of designs and finishes allows for a seamless blend with any décor style.

MOONLIT’s commitment to quality and excellence is reflected in our adherence to stringent manufacturing standards, ensuring that every product we deliver meets international benchmarks. We pride ourselves on fostering long-term relationships with our clients, underpinned by sincerity and mutual growth. By choosing MOONLIT, you align with a company that prioritizes innovation and reliability, offering solutions that enhance value and performance in every project.

PVC Foam Products

The Frequent FAQs of PVC Foam Products

What are PVC profiles?▾

PVC (Polyvinyl Chloride) profiles are versatile and widely utilized components in the construction and manufacturing industries, offering a multitude of applications due to their inherent benefits and adaptability.

At their core, PVC profiles are plastic extrusions crafted from PVC resin. This material, renowned for its durability and cost-effectiveness, is crucial in producing components like window frames, door frames, and decorative trims for both residential and commercial buildings. The extrusion process involves melting the PVC resin and forcing it through a die, which shapes it into various profiles. The versatility in design allows manufacturers to create U-channels, J-channels, and L-channels, among others, catering to different structural needs.

PVC profiles offer a myriad of advantages that make them a preferred choice for numerous applications. Their lightweight nature simplifies handling and installation, reducing labor costs and time. Despite their lightness, they are incredibly durable, resistant to corrosion, and impervious to water damage, which ensures longevity in environments exposed to moisture or varying weather conditions. This makes them particularly suitable for external applications such as window and PVC door frames. Additionally, PVC profiles provide excellent insulation properties, contributing to energy efficiency in buildings by reducing heat loss or gain.

The construction industry is a prominent user of PVC profiles. In modern architecture, PVC door frames and window frames are favored not only for their durability but also for their aesthetic appeal. These profiles can be easily customized with additives like colorants and stabilizers, allowing for a wide range of finishes that cater to different architectural styles. Moreover, their ability to withstand harsh environmental conditions without losing integrity makes them ideal for both coastal and inland constructions.

Beyond construction, PVC profiles find applications in a variety of other sectors. In the electrical field, they are used as conduits for wiring due to their excellent insulating properties. The medical industry also utilizes PVC profiles in the production of critical components like catheters and stents, benefiting from the material's biocompatibility and flexible nature. Furthermore, PVC profiles are increasingly being used in the signage industry, where their ease of customization and lightweight nature is particularly advantageous.

The manufacturing process of PVC profiles continues to evolve, integrating advanced technologies and materials to enhance their properties. The extrusion process can incorporate various additives, allowing manufacturers to tailor the profiles' characteristics to specific requirements, such as increased UV resistance for outdoor applications or enhanced fire-retardant properties for safety. These innovations extend the applicability of PVC profiles even further, opening new avenues for their use.

In conclusion, PVC profiles stand out as a critical component in various industries due to their versatility, durability, and cost-effectiveness. Whether used in constructing robust PVC door frames or in delicate medical applications, these profiles offer solutions that meet diverse needs while ensuring high performance and longevity. As technology progresses, the potential for PVC profiles continues to expand, promising even greater contributions to numerous fields.

Understanding PVC Profiles

At their core, PVC profiles are plastic extrusions crafted from PVC resin. This material, renowned for its durability and cost-effectiveness, is crucial in producing components like window frames, door frames, and decorative trims for both residential and commercial buildings. The extrusion process involves melting the PVC resin and forcing it through a die, which shapes it into various profiles. The versatility in design allows manufacturers to create U-channels, J-channels, and L-channels, among others, catering to different structural needs.

Benefits of PVC Profiles

PVC profiles offer a myriad of advantages that make them a preferred choice for numerous applications. Their lightweight nature simplifies handling and installation, reducing labor costs and time. Despite their lightness, they are incredibly durable, resistant to corrosion, and impervious to water damage, which ensures longevity in environments exposed to moisture or varying weather conditions. This makes them particularly suitable for external applications such as window and PVC door frames. Additionally, PVC profiles provide excellent insulation properties, contributing to energy efficiency in buildings by reducing heat loss or gain.

Applications in Construction

The construction industry is a prominent user of PVC profiles. In modern architecture, PVC door frames and window frames are favored not only for their durability but also for their aesthetic appeal. These profiles can be easily customized with additives like colorants and stabilizers, allowing for a wide range of finishes that cater to different architectural styles. Moreover, their ability to withstand harsh environmental conditions without losing integrity makes them ideal for both coastal and inland constructions.

Versatility in Other Industries

Beyond construction, PVC profiles find applications in a variety of other sectors. In the electrical field, they are used as conduits for wiring due to their excellent insulating properties. The medical industry also utilizes PVC profiles in the production of critical components like catheters and stents, benefiting from the material's biocompatibility and flexible nature. Furthermore, PVC profiles are increasingly being used in the signage industry, where their ease of customization and lightweight nature is particularly advantageous.

Manufacturing Innovations

The manufacturing process of PVC profiles continues to evolve, integrating advanced technologies and materials to enhance their properties. The extrusion process can incorporate various additives, allowing manufacturers to tailor the profiles' characteristics to specific requirements, such as increased UV resistance for outdoor applications or enhanced fire-retardant properties for safety. These innovations extend the applicability of PVC profiles even further, opening new avenues for their use.

In conclusion, PVC profiles stand out as a critical component in various industries due to their versatility, durability, and cost-effectiveness. Whether used in constructing robust PVC door frames or in delicate medical applications, these profiles offer solutions that meet diverse needs while ensuring high performance and longevity. As technology progresses, the potential for PVC profiles continues to expand, promising even greater contributions to numerous fields.

What is PVC window profile?▾

● Understanding PVC Window Profiles

PVC window profiles are an essential component of modern window joinery, responsible for providing structural integrity, insulation, and aesthetic appeal. These profiles are crafted from polyvinyl chloride (PVC), a durable, low-maintenance material known for its resistance to environmental wear and tear. As an integral part of window design, PVC profiles are evaluated based on several parameters that determine their effectiveness and suitability for different applications.

○ Composition and Classification

PVC profiles are classified into different classes based on their wall thickness, a key factor influencing their performance. According to standard specifications, there are three primary classes: A, B, and C. Class A profiles, which exhibit visible wall thickness of at least 2.8 mm and invisible wall thickness of at least 2.5 mm, are often perceived as the most robust due to their superior thickness. Class B profiles follow closely, with slightly thinner walls—2.5 mm for visible walls and 2 mm for invisible walls. Profiles falling under class C do not meet the minimum thickness requirements for the other two classes.

While the classification provides insights into the structural properties of the profiles, it is crucial to understand that these differences in thickness, although significant in manufacturing, do not drastically affect other performance aspects such as thermal insulation and resistance to wind load.

○ Role in Thermal Insulation and Wind Resistance

A common misconception is that Class A profiles inherently offer better thermal insulation than other classes. However, the thermal performance of a window largely depends on factors beyond mere wall thickness. These include the depth of the profile, the number of internal chambers, and the design and material of the steel reinforcement used within the profile. Thus, while the class can indicate certain physical characteristics, it should not be the sole deciding factor for determining a profile's thermal efficiency.

Similarly, the resistance to wind load is not significantly affected by the classification. The strength and stability of a window are primarily due to the steel reinforcements embedded within the profiles. These reinforcements play a far more critical role in ensuring the window can withstand strong winds than the slight variations in profile wall thickness.

○ Advantages of PVC Window Profiles

PVC window profiles offer several advantages that make them a popular choice in both residential and commercial settings. Firstly, PVC is impervious to moisture, which means these profiles are not prone to warping or rotting, unlike wood. They also require minimal maintenance, as they do not need regular painting or sealing.

In addition to these practical benefits, PVC window profiles are available in a variety of designs and finishes, offering versatility in aesthetic choices. This variety allows them to complement a wide range of architectural styles and personal preferences.

○ Integration with PVC Door Frames

PVC profiles are not limited to windows; they are equally important in the construction of PVC door frames. The same principles of durability, maintenance, and design flexibility apply. Just like window profiles, PVC door frames benefit from the material's resistance to weathering and its capability to insulate against temperature variations.

In conclusion, PVC window profiles are a critical element in modern window manufacturing, combining structural strength, aesthetic versatility, and environmental resistance. Understanding the nuances of their classification and the factors influencing their performance can aid in making informed decisions when selecting window and door solutions for any building project.

What size are PVC profiles?▾

PVC profiles are an essential component in numerous industrial and consumer applications, characterized by their versatility and efficiency in production. Understanding the sizes and dimensions of PVC profiles is crucial for tailoring them to specific needs, particularly in projects that require precision and adaptability, such as the construction of PVC door frames.

PVC profiles come in an array of standard sizes, accommodating various needs in construction, automotive, marine, and other industries. The typical range for rigid PVC profiles spans from as small as 0.25 inches to as long as 30 feet or more. This broad spectrum allows for flexibility in design and application, whether you're working on small-scale projects or large-scale industrial installations. For instance, in the context of a PVC door frame, the material can be precisely cut to fit standard door dimensions or customized to accommodate unique architectural requirements.

In addition to length and width, the thickness of PVC profiles is another critical dimension that can be tailored to suit specific applications. Rigid PVC profiles typically range from 0.015 inches to 0.25 inches or more in thickness, offering a robust solution for applications that demand durability. This thickness range ensures that the profiles maintain structural integrity while allowing for flexibility in design choices. For applications like PVC door frames, selecting the appropriate thickness can provide the necessary strength to support the door's weight while ensuring a snug fit within the architectural design.

Beyond standard sizes, PVC profiles can be customized in both shape and color to meet specific project requirements. Manufacturers can produce a variety of cross-sectional shapes, including U-channels, J-channels, and T-sections, among others. This versatility is particularly beneficial for creating bespoke PVC door frames, where specific design elements or architectural features need to be incorporated. Customization extends to color options as well, allowing for color matching with existing designs or branding requirements, thus ensuring a cohesive aesthetic in visible installations.

The choice between rigid and flexible PVC further influences the size and application scope of the profiles. Rigid PVC, known for its durability and weather resistance, is often the material of choice for construction applications like door frames, where structural stability is paramount. Conversely, flexible PVC, made supple with added plasticizers, offers an alternative for situations that require pliability, such as in fitting around curves or uneven surfaces. Understanding the distinction between these two types of PVC and their respective size options enables more informed decision-making for project specifications.

In summary, PVC profiles, with their varied sizes and customizable features, offer a comprehensive solution for a wide range of industrial and consumer applications. Whether standard or customized, these profiles provide the flexibility and durability necessary to meet the demands of modern construction and manufacturing. When considering the specific application of a PVC door frame, understanding the available size options, material characteristics, and customization possibilities ensures that the end product meets both functional and aesthetic requirements. By leveraging the versatility of PVC profiles, one can achieve optimal outcomes in precision and performance, making them an indispensable choice for professionals across multiple sectors.

Standard Sizes of PVC Profiles

PVC profiles come in an array of standard sizes, accommodating various needs in construction, automotive, marine, and other industries. The typical range for rigid PVC profiles spans from as small as 0.25 inches to as long as 30 feet or more. This broad spectrum allows for flexibility in design and application, whether you're working on small-scale projects or large-scale industrial installations. For instance, in the context of a PVC door frame, the material can be precisely cut to fit standard door dimensions or customized to accommodate unique architectural requirements.

● Thickness and Flexibility

In addition to length and width, the thickness of PVC profiles is another critical dimension that can be tailored to suit specific applications. Rigid PVC profiles typically range from 0.015 inches to 0.25 inches or more in thickness, offering a robust solution for applications that demand durability. This thickness range ensures that the profiles maintain structural integrity while allowing for flexibility in design choices. For applications like PVC door frames, selecting the appropriate thickness can provide the necessary strength to support the door's weight while ensuring a snug fit within the architectural design.

Customization for Specific Applications

Beyond standard sizes, PVC profiles can be customized in both shape and color to meet specific project requirements. Manufacturers can produce a variety of cross-sectional shapes, including U-channels, J-channels, and T-sections, among others. This versatility is particularly beneficial for creating bespoke PVC door frames, where specific design elements or architectural features need to be incorporated. Customization extends to color options as well, allowing for color matching with existing designs or branding requirements, thus ensuring a cohesive aesthetic in visible installations.

● Rigid vs. Flexible PVC

The choice between rigid and flexible PVC further influences the size and application scope of the profiles. Rigid PVC, known for its durability and weather resistance, is often the material of choice for construction applications like door frames, where structural stability is paramount. Conversely, flexible PVC, made supple with added plasticizers, offers an alternative for situations that require pliability, such as in fitting around curves or uneven surfaces. Understanding the distinction between these two types of PVC and their respective size options enables more informed decision-making for project specifications.

Conclusion

In summary, PVC profiles, with their varied sizes and customizable features, offer a comprehensive solution for a wide range of industrial and consumer applications. Whether standard or customized, these profiles provide the flexibility and durability necessary to meet the demands of modern construction and manufacturing. When considering the specific application of a PVC door frame, understanding the available size options, material characteristics, and customization possibilities ensures that the end product meets both functional and aesthetic requirements. By leveraging the versatility of PVC profiles, one can achieve optimal outcomes in precision and performance, making them an indispensable choice for professionals across multiple sectors.